Air Differential Friction Shaft for High Speed Slitter

jeremy@magnimachinery.com

www.magnimachinery.com

Jeremy Jing

www.magnimachinery.com

我的简介

2018年6月21日星期四

2018年6月20日星期三

3inch Ball Type Differential Air Friction Shaft

3inch Ball Type Differential Air Friction Shaft

jeremy@magnimachinery.com

www.magnimachinery.com

jeremy@magnimachinery.com

www.magnimachinery.com

3inch Differential Air Friction Shaft (15mm width) For Narrow Rolls

3inch Differential Air Friction Shaft (15mm width) For Narrow Rolls

jeremy@magnimachinery.com

www.magnimachinery.com

jeremy@magnimachinery.com

www.magnimachinery.com

2016年12月2日星期五

Differential Air Shaft,Friction Shaft,Friction Ring-For High Speed Slitting Machine

Brand: MAGNI MACHINERY

Product Description of Air Differential Rewinding Core Shafts

The ball type pneumatic air differential shaft is applied mainly to wind shaft, or unwind shaft in special occasions.

The body of the air differential shaft is made from chrome-plate steel or hard anodized aluminum. The friction plate can be made from polyurethane, polyethylene, or rubber to max tension required.

To meet our customers’ special requirements, according to the drawing, we can make steel shaft head with different sizes.

Feature of Air Differential Rewinding Core Shafts

- Difference in material thickness often arises when unwinding plastic films or other material. In the process of constant winding, this difference can lead to obvious discrepancy in outside diameter of roll, and slight discrepancy in winding torque under this situation.

- After some winding rotation, some rolls may become very tight, and meanwhile, some other rolls may start to loosen, leasing to quality decline in product eventually.

- Our differential air shaft with slipping friction can ensure the highest winding quality, and by keeping proper tension on all rolls throughout the winding operation, materials will not show any problem.

- It works under the theory that friction rings slip constantly in center of air shaft, and to keep same tension, some rings slip faster than others. So tension of each roll can be controlled accurately, and permanent tension can also be gained to guarantee the quality of roll.

- According to different roll diameters, to control air pressure of air bag and to guarantee tension, a constant air pressure source kept by rotary joint is required.

Technical parameter of Air Differential Rewinding Core Shafts

Applicable roll inside diameter (mm)

|

50.8

|

70

|

76.2

|

152.4

|

Non-swell diameter (mm)

|

50

|

69

|

75

|

151.5

|

Weight journals not included(kg×m)

|

12

|

27

|

32

|

61

|

Maximum torque (Nm/m)

|

21

|

29

|

32

|

64

|

Application of Air Differential Rewinding Core Shafts

Packaging and Shipping of Air Differential Rewinding Core Shafts

Welcome to contact us

2016年6月12日星期日

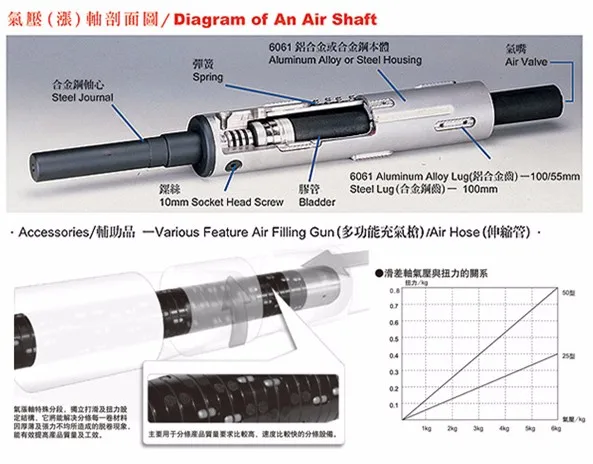

1.5"/2"/3"/4"/5"/6"/12" Lug Type And Leaf Type Air Expanding Shaft(Aluminum or Steel)

Introduction of lug type/leaf type air shaft

The leaf type air expanding shaft is applicable to winding and unwinding shaft of the related machines in coating ,cutting ,printing ,compounding ,paper making, bag making, plastic items, specially the occasion of the high-efficient roundness required or surface winding and unwinding of the paper tube. Moreover,leaf type air expanding shaft also can improve efficiency and quality of the products.

Structural Features of lug type/leaf type air shaft

The leaf type air expanding shaft utilizes the aluminum tiles with flexible scalability, deploying high quality rubber bladder and rapid aerating and exhausting gas nozzle with good sealing effect and long service life,air shafthas removable shaft with simple maintenance.

Advantages of lug type/leaf type air shaft

- Inflatable job a short time, separated from the leaf type air expanding shaft and place the paper tube just three seconds to inflate and deflate, nor do they need any parts sub negligent shaft side that is able to work closely with the paper tube bite.

- Paper tube placement simple: inflatable and deflated operation, mobile and fixed any position paper tube in the axial plane.

- Carrying heavy: May be the actual needs of customers, to determine the size of the shaft diameter, and the use of high strength steels hard to make it carry the weight increase.

- Economic efficiency: shaft design for a particular function, for thick, thin, wide, narrow tubes have encountered all kinds of paper of all applications.

- Maintenance is simple, use a long time: a single leaf type air expanding shaft parts, each part in its construction has fixed specifications, can exchange it with, it is convenient.

Technical parameter of lug type/leaf type air shaft

Item

|

1.5"shaft

|

3"shaft

|

6"shaft

|

12"shaft

|

Ppaer tube inner dia

|

Φ38.1mm

|

Φ76.2mm

|

Φ152.4mm

|

Φ304.8mm

|

Shaft dia before expanding

|

Φ37mm

|

Φ74mm

|

Φ150mm

|

Φ302mm

|

Shaft dia after expanding

|

Φ40mm

|

Φ79mm

|

Φ156mm

|

Φ308mm

|

Order guide of lug type/leaf type air shaft

Users should specify type,dimension,the position of the gas nozzle,and the tolerance of the important size of the top of shaft.If the air shaft inlet gas,when the gas nozzle is mounting,the out diameter of the top of the leaf type air expanding shaft should be more than 35mm;All formal drawing of overall dimension should be provided.After the confirmation of both sides,we will start production.

Application of lug type/leaf type air shaft

Shipping and Packaging of lug type/leaf type air shaft

Contact Us Now

www.magnimachinery.com

jeremy@magnimachinery.com

Skype: luckytime_jeremy

Skype: luckytime_jeremy

MAGNI 325/425 Cross-Cut Strip Cut Cardboard Paper Shredder

MAGNI 325/425 Cross-Cut Strip Cut

Cardboard Paper Shredder

Cardboard Paper Shredder

Hot Selling~!!!

INTRODUCTION OF 425 Cross-Cut Cardboard Paper Shredder

The 325 series of cardboard paper machine is special made as the cardboard-box factory supporting products, cost-effective,.

Microcomputer control, cardboard ultra width automatic cutting;

Dealing with unqualified paper board,carton,color box,paper box…etc.it can make the corrugated carton become a free soft green environmental protection packing material,and it’s also used to fragile goods transport packaging.

TECHNICAL DATA OF 425 Cross-Cut Cardboard Paper Shredder

TYPE

|

325

|

425

|

Mode

|

Half open feed

|

Half open feed

|

Width of paper

|

325mm

|

425mm

|

Thickness

|

20mm

|

20mm

|

Shredded shape

|

5×60mm cross cut

(or 5mm strip cut)

|

5×100mm cross cut

(or 5mm strip cut)

|

Thickness of shredded paper

|

3-5 layer corrugated paper;

30-40PCS

A4/70g paper

|

5-7 layer corrugated paper;

40-70 PCS

A4 70g paper

|

Speed

|

12 m/min

|

12 m/min

|

Noise(db)

|

60

|

60

|

Power

|

220V /50Hz

|

380V/50Hz

|

Rated Power

|

1.8KW

|

2.8KW

|

Weight

|

90Kg

|

165Kg

|

Dimension

|

W 500×L 355×H 800mm

|

W 700×L680×H970mm

|

Package Size

|

W670×L490×H1030mm

|

W830×L635×H1240mm

|

Total Weight

|

116Kg

|

207Kg

|

APPLICATION OF 425 Cross-Cut Cardboard Paper Shredder

Cardboard After Shredding

WELCOME TO CONTACT US

www.magnimachinery.com

jeremy@magnimachinery.com

订阅:

评论 (Atom)